If individual locks or tags are used the individual responsible for designating the lockout tagout and the individual responsible for it during the next shift must both be present as.

Lock out tag out mobile equipment.

They re commonly used on machinery electrical equipment and plumbing systems to reduce the risk of injuries from unexpected startups.

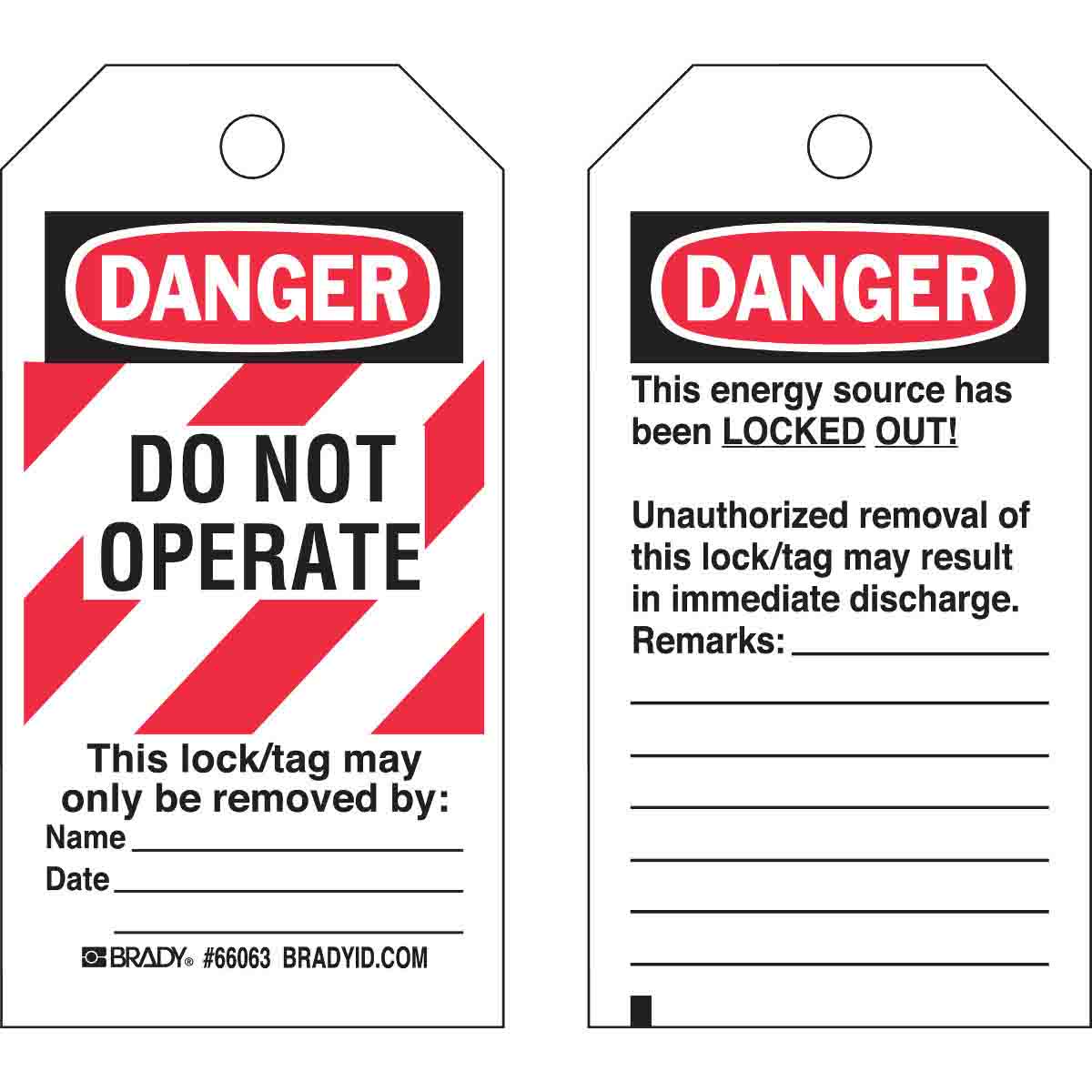

Then the individual must either lock or tag the machinery to prevent any accidental startup.

Lockout tagout loto products lock down equipment to keep it from being powered on down during maintenance and repair work.

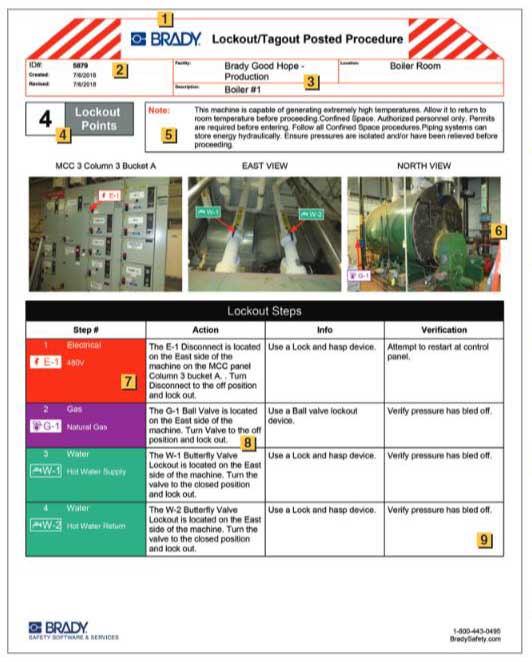

Loto procedures help to control hazardous energy.

Locking if the machinery allows provides the best level of protection.

A designated individual must first turn off and disconnect the machinery from its energy source.

It s fair to say that this entire six step process takes its name from this step.

With the machine or equipment isolated from its energy source the next step of lockout tagout is to actually lock and tag out the machine.

Andrew jarrett created date.

Loto tool box talk author.

Equipment is locked out.

Are you looking for something specific.

The equipment must remain in lockout tagout condition across shift changes so that workers arriving at the site are aware that the equipment is out of service.

Equipment identification and cataloguing energy control tags and lockout tagout signage should also be implemented.

Lock out all energy sources.

The best way to enforce your safety lockout program is with equipment locked out tags that grab attention.

For product information delivery queries or expert advice please contact us directly at 057 866 2162 or email us at email protected.

Lock out tag out audits should be run regularly.

During this step the authorized employee will attach lockout and or tagout devices to each energy isolating device.

Only the person who put on the lock and tag removes it.

The lock out tag out try out process consists of important procedures cemex mechanics take in order to safeguard themselves as well as others from the rele.

All employees who work in an area where energy control procedure s are utilized need to be instructed in the purpose and use of the energy control procedure s especially prohibition against attempting to restart or reenergize machines or other equipment that are locked or tagged out.